Wine Labels

CARTES manufactures the most advanced Embellishment and Laser Die Cutting Machinery offered for the manufacturing of wine labels.

We would like to share an amazing article that talks about Embellishments and Digital Printing of Wine Labels. This article was published in Label & Narrow Web Magazine in the January/February 2021 issue. The article talks about the new state-of-the-art Embellishment and Digital Print Technology.

As seen in Label & Narrow Web January/February 2021

To view the full article please visit www.labelandnarrowweb.com

[…]

Wine labeling – much like the liquid encapsulated within – is a science. There is a premium on diversity, and in most cases, the wine label impacts the sale.

[…] “Today’s consumers have hundreds of wine choices available and they make their purchase decision in seconds, largely based on label design,” says Brendan Kinzie, president of wine and spirits at Fortis Solutions Group. “The label must stand out in a sea of bottles on the shelf and make an emotional connection with the consumer. The design is key to making this happen. We are seeing wine label designs trend towards richer, thicker uncoated paper stocks and an increasing amount of tactile features such as embossing, debossing, foil stamping, and screen high-builds.”

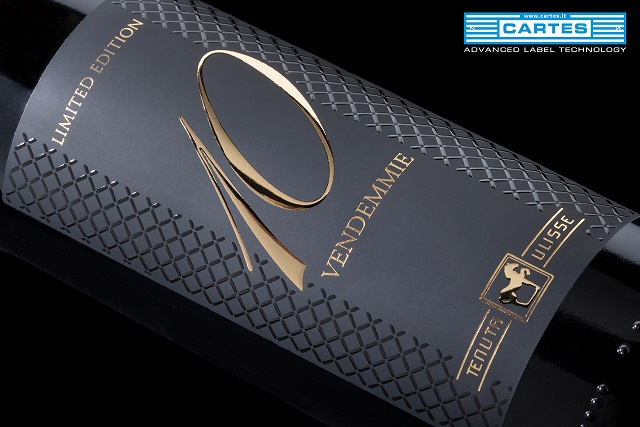

[..] “Wine and liquor labels have undergone constant changes, all focused on product diversification to achieve a high appearance value that goes beyond product quality,” notes Enrica Lodi, sales and marketing manager at Cartes. “Therefore, products are constantly aiming at looking good, regardless of the price or market rating. The large number of substrates – now available with textures and visual effects – as well as the technologies that help enhance these effects, are intimately connected to the creativity of the designs. These all characterize a worldwide trend that is growing by leaps and bounds.”

[..]

A need to embellish?

Embellishments are a great design technique used to convey luxury and quality to prospective wine shoppers.

“Embellishments give depth to the design and add to the tactile look and feel of a label,” comments Fortis’ Kinzie. “Embellishments, like foil stamping, embossing and debossing, enhance brand equity by adding to the luxury positioning of the wine brand while at the same time communicating the promise of quality to the consumer.”

According to Cartes, special effects are constantly sought after for anti-counterfeiting, differentiation, brand footprint, advertising impact, an attractive appearance to match product quality, among others.

“The wine and spirits industry is increasingly focused on attracting consumers by embellishing every detail of the product,” explains Cartes’ Lodi. “A very important part of these developments has been applied to the label, as there are several possibilities to make it stand out while keeping costs contained. A large number of wines and spirits displayed on the shelf are gift items, and so the best-looking ones always resonate more. Furthermore, fierce competition from emerging markets has forced traditional products to step out of their comfort zone to make a difference, since many times the buyer is not aware of the product and ends up buying it only for the appearance.”

Cartes has specialized in providing equipment to better serve this market. The company has developed technologies to ensure the premium look of the label. Cartes’ machines can be configured to highlight the products with top-end added-value applications, adds Lodi.

“The versatility of our machines is outstanding, as they can be specifically configured according to customers’ needs – plus, they can be upgraded with new units and special devices,” she states. “For wine labeling, several configurations can be combined with units for digital and conventional flat-bed screen printing, hot stamping and embossing, flexo coating and printing, flat-bed and semi-rotary diecutting, as well as laser converting applications. Our special gadgets can also be added to create multiple effects such as labels on labels, cut-off window, metallic doming, invisible laser cutting, IML processing and more.”